The term "CNC" has become a cornerstone in modern manufacturing and industrial processes, revolutionizing the way we produce goods and components. Standing for Computer Numerical Control, CNC refers to the automation of machine tools using computers to execute pre-programmed sequences of machine control commands. Unlike manual control, where operators need to guide the machine tools by hand, CNC technology offers unparalleled precision, efficiency, and repeatability, making it a preferred choice in various industries such as aerospace, automotive, and medical device manufacturing.

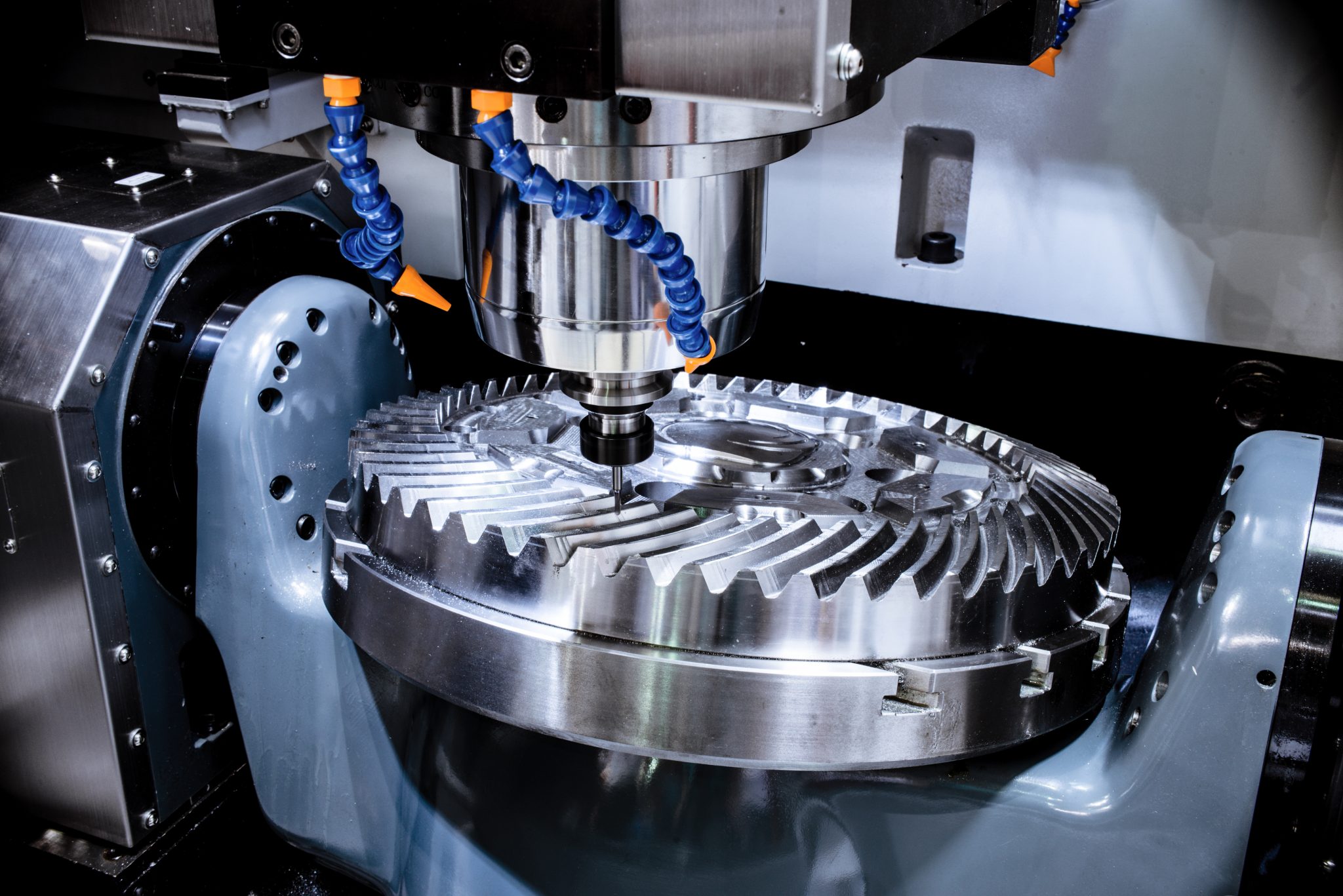

At its core, CNC represents a blend of computer technology and mechanical engineering. This powerful combination allows manufacturers to create complex shapes and designs that would otherwise be impossible or extremely labor-intensive to produce using traditional methods. From 3D milling and laser cutting to plasma cutting and electrical discharge machining, CNC machines serve as the backbone of modern manufacturing, enabling the creation of everything from intricate jewelry pieces to massive aircraft components.

The importance of CNC goes beyond just manufacturing; it has paved the way for innovation across numerous fields. By reducing human error and increasing production speed, CNC technology has significantly lowered costs while maintaining high-quality standards. As industries continue to adopt smarter and more efficient manufacturing techniques, understanding the CNC meaning becomes crucial for anyone looking to navigate the ever-evolving landscape of industrial automation and technology.

Table of Contents

- What Is CNC?

- History and Evolution of CNC

- How CNC Machines Work

- Common Components of CNC Machines

- Types of CNC Machines

- Applications of CNC Machining

- Advantages of CNC Technology

- Challenges and Limitations

- CNC Programming Languages

- CNC in Modern Industries

- Future of CNC Technology

- CNC vs. Traditional Machining

- How to Choose the Right CNC Machine

- Maintenance and Safety Tips

- FAQs About CNC Meaning

What Is CNC?

Computer Numerical Control, or CNC, refers to the automation of machine tools through the use of computers to control their movements. These machines are pre-programmed with specific instructions, which dictate how the tools operate and interact with the materials they are working on. The technology allows for a high level of precision and complexity, which is difficult to achieve with manual methods.

CNC machines can perform a variety of tasks, including cutting, drilling, milling, turning, and engraving. By using advanced software to translate digital designs into physical products, CNC has become a standard in industries ranging from aerospace to consumer electronics.

This is the initial part of your article. Let me know if you'd like me to continue building the content for each of the outlined headings or make any adjustments!

Article Recommendations

- Mitch Mcconnells Anger Latest Outburst Explained

- Gift Box With Window The Perfect Packaging Solution For Every Occasion

- Mark Mcgraw Actor Producer And Philanthropist